Mafi ingancin 1000W / 1500W / 2000W / 3000W Fiber Laser Welding / Laser Welder / Laser Yankan / Laser Cleaning Machine don Bakin Karfe / Aluminium / Brass / Copper / Carbon Karfe

Muna jaddada ci gaba da gabatar da sababbin samfurori a kasuwa kowace shekara don Mafi kyawun 1000W / 1500W / 2000W / 3000W Fiber Laser Welding / Laser Welder / Laser Cutting / Laser Cleaning Machine don Bakin Karfe / Aluminium / Brass / Copper / Carbon Karfe, Bari mu hada kai. hannu da hannu don samar da kyakkyawar makoma mai kyan gani. Muna maraba da ku da gaske don ziyartar kamfaninmu ko kuma ku kira mu don haɗin gwiwa!

Muna jaddada ci gaba da gabatar da sababbin samfurori a kasuwa kowace shekara donChina Laser Weld Machine da Welding Machine, Mun samu fiye da 200 ma'aikata ciki har da gogaggen manajoji, m zanen kaya, sophisticated injiniyoyi da ƙwararrun ma'aikata. Ta hanyar aiki tuƙuru na duk ma'aikata a cikin shekaru 20 da suka gabata kansa kamfani ya ƙara ƙarfi da ƙarfi. Kullum muna amfani da ƙa'idar "abokin ciniki na farko". Har ila yau, koyaushe muna cika duk kwangiloli har zuwa ma'ana don haka muna jin daɗin kyakkyawan suna da amana tsakanin abokan cinikinmu. Kuna marhabin da ku ziyarci kamfaninmu da kanku. Muna fatan fara haɗin gwiwar kasuwanci bisa ga fa'idar juna da ci gaba mai nasara. Don ƙarin bayani ku tabbata ba ku yi shakka a tuntube mu..

PARAMETER

| Ƙarfin Laser | 100W/200W/500W |

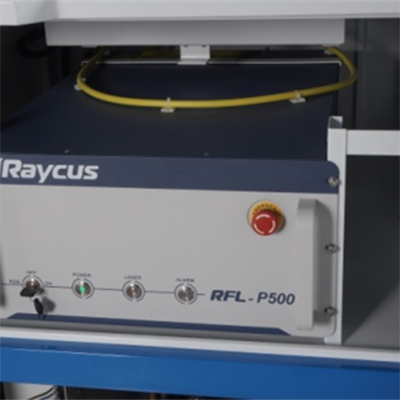

| Nau'in tushen Laser | Raycus, IPG don zaɓi |

| Laser tsawon zangon | 1064 nm |

| Hanyar sanyaya | Ruwa sanyaya |

| Ruwan sanyaya | Deionized ruwa |

| Yanayin zafin ruwa | 18-22 ° C |

| Duba fadin | 10-60 mm |

| Gas mai taimako | Matsewar iska/Nitrogen |

| Matsin iska | 0.5-0.8 MPa |

| Na'urorin haɗi na zaɓi | Hannu / Manipulator |

| Yanayin aiki | 5-40 ° C |

FALALAR

- Daidaitaccen tsaftacewa na laser don ainihin matsayi da girman girman girman.

- Aiki mai sassauƙa don yanki na aiki tare da rikitacciyar gini na geometric za a iya gane shi ta hannun tsaftacewa na laser na hannu.

- An yi amfani da shi sosai a cikin lebur, mai lanƙwasa da ƙasa mai girma uku don yanki na kayan aiki na roba da filastik tare da ƙananan ramuka da zurfi.

- Amintacce & mutunta muhalli. Ba tare da amfani da wankan sinadari ko sauran abubuwan amfani ba

- Tsaftacewa mara lamba kuma babu lalacewa ga ma'auni mai ƙarfi.

- Sauƙi don aiki, tare da yanayin šaukuwa kuma ana iya sanye shi da robot don tsaftacewa ta atomatik

- Babu kulawa kuma babu kayan amfani, mara ƙura, babu sinadarai, babu gurɓata.

- Low tsaftacewa kudin da High tsaftacewa dace.

APPLICATION

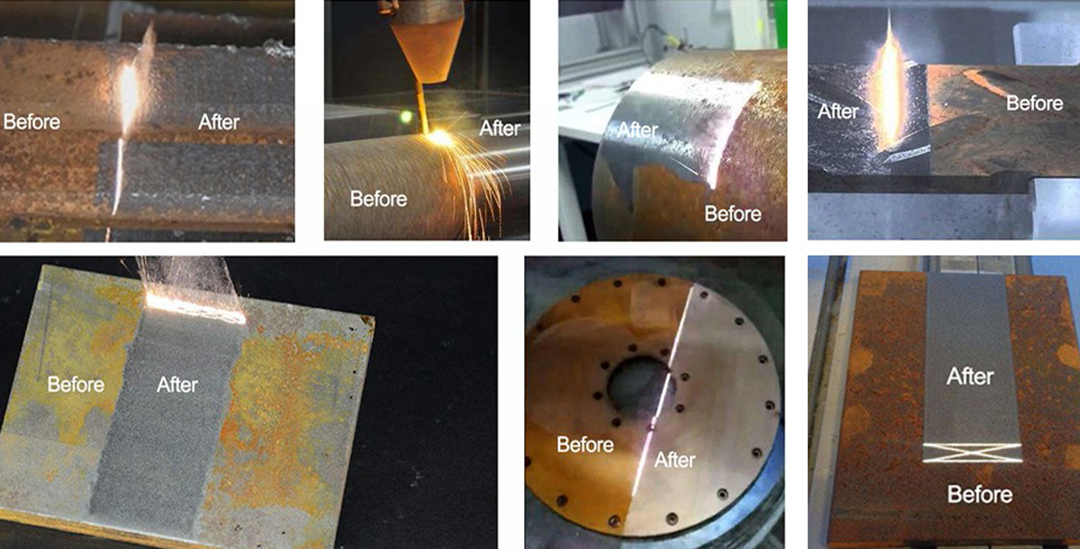

Karfe surface tsatsa kau

Tsabtace fenti

Tsabtace mai / gurɓataccen mai

Shafi surface tsaftacewa

Welding / shafi surface pre-jiyya

Dutsi adadi saman kura & abin da aka makala tsaftacewa

Filastik mold saura tsaftacewa

BAYANI

KA'IDA

Bambanci tsakanin ci gaba da Laser da bugun jini Laser tsaftacewa:

Bayan tsaftacewa mai haske, an cire Layer fenti a saman samfurin gaba daya, kuma saman samfurin ya bayyana. Karfe fari, kuma kusan babu lalacewa ga samfurin substrate. Bayan tsaftacewa tare da ci gaba da haske, an cire Layer fenti a saman samfurin gaba daya, amma saman samfurin ya bayyana launin toka-baki, kuma substrate na samfurin kuma ya nuna ƙananan narkewa. Don haka, amfani da ci gaba da haske yana iya haifar da lahani ga ma'auni fiye da hasken da aka buga.

Dukansu ci gaba da laser da pulsed laser na iya cire fenti a saman kayan don cimma tasirin tsaftacewa. A ƙarƙashin yanayin wutar lantarki guda ɗaya, ingancin tsaftacewa na laser pulsed ya fi girma fiye da na ci gaba da laser. A lokaci guda, pulsed Laser iya mafi kyau sarrafa zafi shigarwa don hana wuce kima zafin jiki na substrate ko micro-narke.

Laser ci gaba yana da fa'ida a cikin farashi, kuma rata a cikin inganci tare da laser pulsed ana iya yin ta ta hanyar amfani da laser mai ƙarfi, amma hasken ci gaba mai ƙarfi yana da mafi girman shigarwar zafi, kuma lalacewar ma'aunin zai kuma ƙaruwa. Don haka, akwai babban bambanci tsakanin su biyun a cikin yanayin aikace-aikacen. Don aikace-aikacen da ke da madaidaicin madaidaicin, ya kamata a zaɓi tsauraran kula da hauhawar zafin jiki, da abubuwan da ba su lalacewa ba, kamar gyaggyarawa, Laser pulsed. Don wasu manyan sassa na karfe, bututun bututu, da dai sauransu, saboda girman girma da saurin zafi mai zafi, abubuwan da ake buƙata don lalacewar substrate ba su da yawa, kuma ana iya zaɓar ci gaba da laser.

Amfanin Laser pulsed:

Laser pulsed yana haifar da ƙarancin zafi, yayin da ci gaba da laser yana haifar da ƙarin zafi, wanda shine dalilin da yasa Laser mai ƙarfi ke amfani da bugun jini. Laser ƙwanƙwasa na iya sa janareta na Laser ya huta na ɗan lokaci, yayin da ci gaba da zumudi zai iya sa Laser ɗin ya ci gaba da tsayawa ba tare da katsewa ba. aiki, yana da sauƙi don rage rayuwar janareta na laser.

MISALI